Uncategorized

Give Your C1 Corvette Rear Springs a Little R&R

EATON Detroit Spring can make these unavailable first-gen parts like new again.

DETROIT, MICHIGAN: If your first-generation Corvette rear springs are looking a little worn out, it might be time for some R&R, courtesy of EATON Detroit Spring.

DETROIT, MICHIGAN: If your first-generation Corvette rear springs are looking a little worn out, it might be time for some R&R, courtesy of EATON Detroit Spring.

Original C1 Corvette rear springs were made with spring steel that had a groove in the bottom side of each spring leaf. This grooved steel has not been produced since the mid-’60s, so the original-style springs with the groove can no longer be made.

This predicament could bring many restorations to a standstill. However, for springs that are not fatigued, EATON offers an R&R process that can make them as close to new as possible.

R&R stands for Re-temper & Re-arch:

The re-temper process removes the temper from each leaf, then puts it back in;

To re-arch, while red-hot and before they are re-tempered, each leaf is formed back to its original shape.

They then go into an oil bath after being annealed and reshaped. The next step is to go through the second heat-treat furnace that finalizes the re-tempering process. Once through the second heat-treat furnace, the leaves are shot peened to relieve the inherited stresses caused by the heat-treating process before being assembled.

Does it work? Mike Eaton points to a successful job for a prominent client.

“We had a customer in this morning who happens to be the designer of the original Corvette suspension who I have known for years,” he said. “He brought in a couple of sets of C1 rear springs to be reconditioned. Even though we do a lot of these, there are a lot of ’Vette owners who don’t know we offer it.”

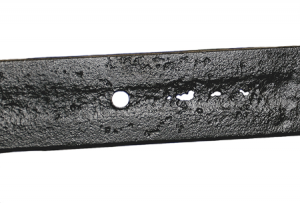

This is fatigued leaf. If your springs look anything close to this, they are not candidates for reconditioning.

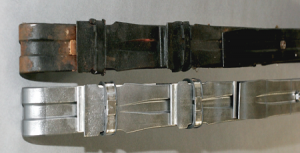

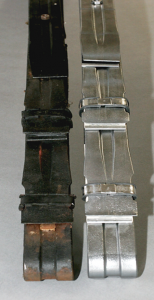

These are good leaves before re-tempering and shot peening.

Leaf coming out of the first heat-treat furnace.

Re-shaped leaf going into oil bath after being annealed and re-shaped. Next step is to go through the second heat-treat furnace that finalizes the re-tempering process.

Once through the second heat-treat furnace the leaves are shot peened before being assembled.

Before and after.